Capabilities

Quality Engineered by Experience

Make a Lasting First Impression.

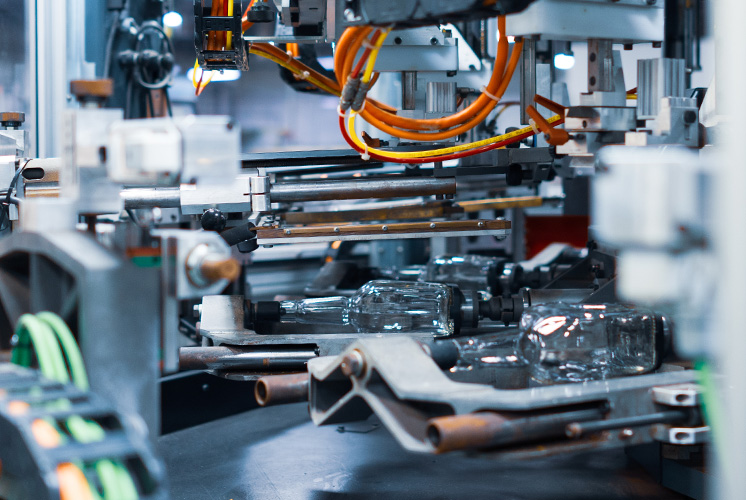

For over three decades, Chattanooga Labeling Systems has been dedicated to perfecting the intricate art of glass decoration. This enduring commitment ensures that our clients can place their trust in nothing short of the best. Our capabilities transcend the ordinary, incorporating state-of-the-art technology, precision machinery, and a highly skilled team. The result? A guarantee that your brand is etched into the memory of consumers as they encounter your product on the shelf.

Screen Printing/Applied Ceramic Labeling

Your design, applied to glass containers with ceramic ink through an automated screen printing machine. After paint application, the design is bonded to the glass by heat inside a lehr furnace, creating a permanent decoration that is scratch-resistant and waterproof.

- Capable of 360° decoration

- Various color options

- Permanent and durable design

- Tight registration

- High daily output with multi-shift production crews

Machinery:

- Four automatic screen printing presses

Spray Coatings

- Capable of 360° spray application

- Transparent spray

- Opaque spray

- Metallic spray

- Variety of color options

Machinery:

- Robotic 2-gun Spray Line with IR pre-cure oven and low-temperature lehr

Medallion Application

Your emblem or artwork, printed onto medallions in a metal of your choice and applied to glass containers by our medallion robot.

- Various metals and plastics available for use with medallions

- Embossed or printed

- Variety of color options

Machinery:

- Custom-built Medallion Application Robot with Keyence Vision System

Water Slide Decal Application

Your artwork, immersed in a water bath and applied by hand to a glass container. After the decal is applied, it is cured through a lehr furnace and permanently bonded to the glass.

- Capable of 360° label application

- Accommodates a wide range of designs

- Applicable on most bottle shapes

- Ideal for use on complex glass shapes

Machinery:

- Done by hand

Pressure Sensitive Labeling

Your design, printed onto paper labels with adhesive backing and rolled onto glass containers by an automated labeling machine.

- Rapid application speed

- Secure adhesion through pressure application

Machinery:

- Automatic Pressure Sensitive Labeling Line

Repack and Re-sort

Carton/Partition Erecting

Your knock down cartons, erected and glued by our robotic carton erector at a rapid rate. Inner packaging such as corrugated or fiberboard partitions are inserted.

Machinery:

- Robotic Carton Erector

Precious Metals

Your design, applied to glass containers in the desired precious metal ink through an automated screen printing machine. After ink application, the design is bonded to the glass by heat inside a lehr furnace, creating a permanent decoration. Ideal for prestigious branding and high value products.

- Can be applied with other ceramic colors

Machinery:

- Four automatic screen printing presses

Striking

Glass containers formed with cuprous oxide by your glass manufacturer are fired in a lehr furnace to produce a black color. A highly controlled operation, with hourly transmission light measurements of glass opacity and extensive quality control processes.

- Provides UV protection for product

Machinery:

- Lehr furnace to heat glass

- Wet saw to cut glass for QC samples

- Spectrophotometer to measure glass opacity